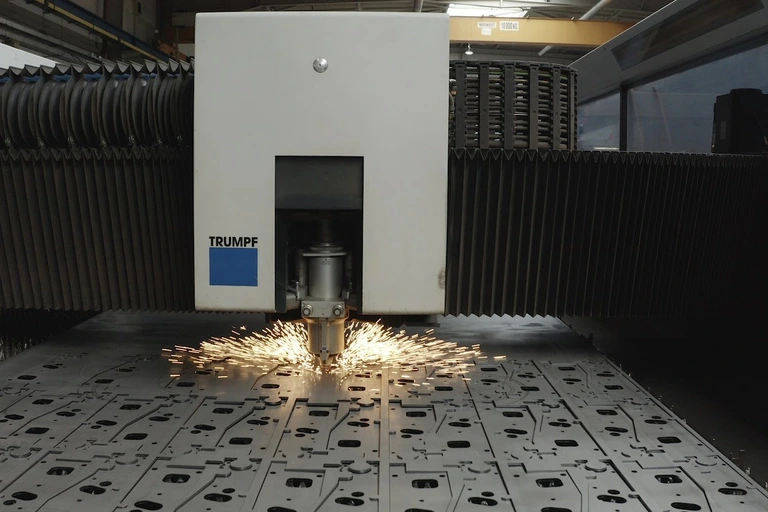

CNC Laser sheet metal cutting

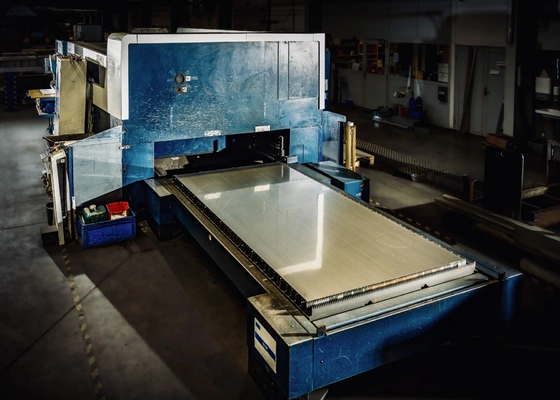

We offer flat cutting of steel, stainless steel, aluminium and copper sheets of max. 2000 x 4000 mm format using two 5 kW and 10 kW Trumpf lasers. We can also burn into foiled and sanded sheets. Programming is implemented in TruTops and TruTops Boost.

Laser cutting of sheet metal is a fast and productive method of thermal splitting of material. Combined with the achievable relative accuracy of about ± 0.1 mm, it is an unrivalled method of sheet metal processing.

TruLaser 5030 FIBER

- Sheet metal processing to size: 1500 × 3000 mm

- Power 5 kW

- Accuracy: ± 0.1 mm

- Carbon steel: 15 mm

- Stainless steel: 10 mm

- Aluminium: 10 mm

- Copper: 6 mm

TruLaser 5040 FIBER

- Sheet metal processing to size: 2000 × 4000 mm

- Power 10 kW

- Accuracy: ± 0.1 mm

- Carbon steel: 40 mm

- Stainless steel: 25 mm

- Aluminium: 15 mm

- Copper: 6 mm