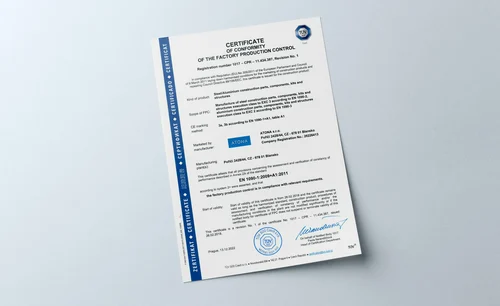

Certifikáty

Materiály odebíráme od evropských výrobců. Vlastníme nadstandardní certifikáty.

Analýza spektrometrem

V rámci zakázek provádíme určení obsahu kovů pomocí přesného spektrometru. Analýzu si můžete pro své potřeby objednat i individuálně.

Dodáváme do celé Evropy

Spolupracujte s námi. Ať už podnikáte kdekoliv.